A controlled environment in blast rooms enhances efficiency and precision in shipyard overhauls, airplane maintenance, and structural steel treatment. It ensures consistent abrasive media application, fewer contamination risks, and faster post-blast clean-up, reducing unpredictability and adhering to tight project timelines.

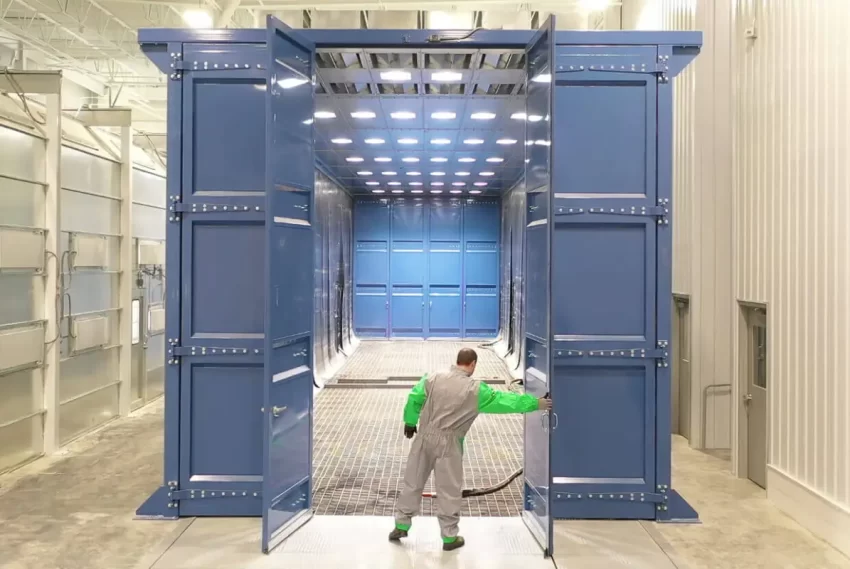

Surface preparation is a pivotal step in delivering high-performance finishes and structural durability, particularly in industrial fields where coatings and corrosion resistance are mission-critical. The precision and cleanliness achieved inside a dedicated blast room are unmatched when compared to open-air blasting alternatives. An Airblast AFC blast room is designed to safely contain abrasive particles, dust, and rebound, ensuring that both the workforce and expensive equipment in nearby areas remain protected from potential hazards.

Why Safety and Air Quality Matter Most

Airborne particulates, particularly those from abrasive materials or hazardous paint removal, can pose severe health risks if not managed properly. OSHA mandates strict dust control rules, including blast room ventilation and dust collector systems.

Modern blast rooms use adverse pressure environments and high-efficiency filtration units to keep dust contained, enhance visibility, reduce slip hazards, and support detailed work. Companies also implement wearable air quality monitors, environmental sampling, and strict cleaning schedules to reduce occupational illness risk and improve worker morale.

Components of an Effective Blast Room

A blast room is crucial for a safe and productive work environment. Its core components include a blast machine, dust collector, media recovery and recycling, entry vestibule, operator safety gear, and proper lighting. The blast machine meters abrasive media for surface preparation, while the dust collector captures airborne particles.

Media recovery and recycling systems use cyclones, vibratory screens, and airwash units to separate debris and fine dust from reusable media. The entry vestibule isolates work areas, while operator safety gear supports regulatory compliance and safety outcomes. Industrial-grade LEDs provide superior brightness and longevity.

Operational Best Practices

Blast room performance relies on daily activities and ongoing process reviews. Best practices include equipment inspections, comprehensive operator training, air quality checks, scheduled maintenance, and incident logging. These measures help detect wear and prevent failure.

Digital systems log incidents for long-term tracking and incident follow-up. Regular maintenance prevents dust buildup and ensures optimal reclaim and filtration parts functioning. Prioritizing these routines increases workforce retention, reduces injuries, and improves project delivery.

Outlook: The Future of Blast Room Innovation

Blast rooms are evolving with automation, smart diagnostics, and integration with facility-wide data networks. Artificial intelligence could optimize blast cycles, predict maintenance needs, and suggest process tweaks for better environmental performance. Adopting modern blast rooms is a foundation for sustainable, safe, and adaptable business growth, preparing companies for future standards in city bridges and historical building restorations.